CARBIDE GRADES

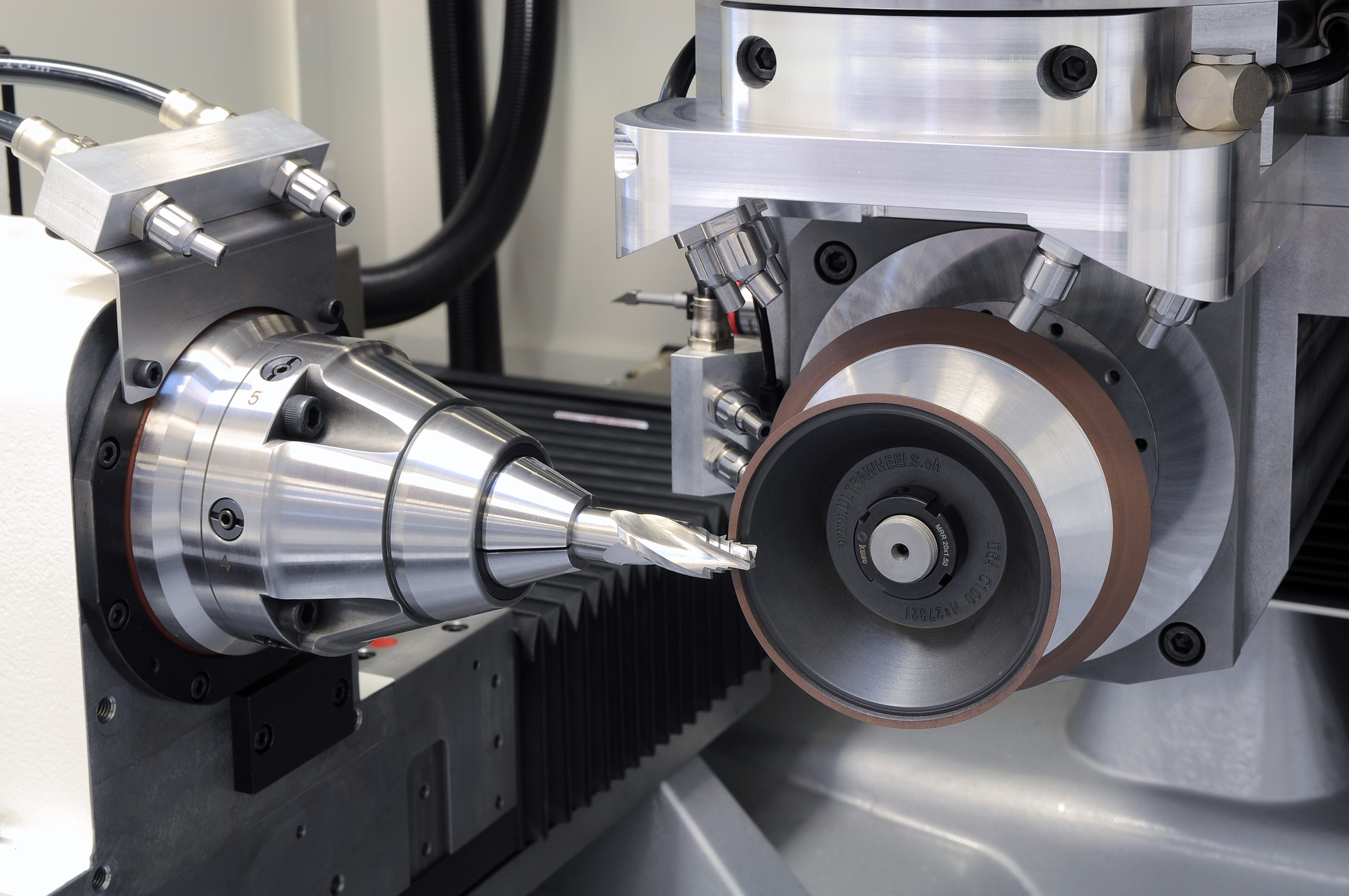

Specializing in Solid Carbide Products

Grades are a way to classify different make ups of cobalt and tungsten carbide within a tungsten carbide product.

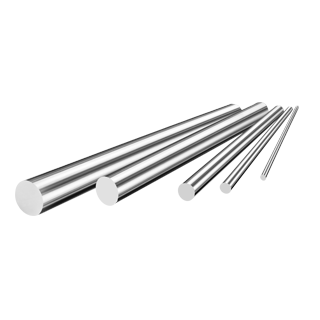

We stock carbide blanks in the following grades. You will see these grades referenced on the product pages.

We obtain our carbide material from more than one manufacturer. Specifications for a particular grade may vary somewhat by manufacturer. The specifications shown below are representative of the different grades and allow for a general comparison between grades.

C-2 Carbide

- Hardness: 92.1 Ra

- Strength: 325,000 psi

- Cobalt Content: 6%

- Avg. Grain Size: 1.2 micron

- Characteristics: General purpose grade, excellent wear resistance, more heat resistant than 10% cobalt grades.

Micrograin Carbide

- Hardness: 92.0 Ra

- Strength: 450,000 psi

- Cobalt Content: 10%

- Avg. Grain Size: .8 micron

- Characteristics: General purpose grade, excellent wear resistance, more impact resistant than C-2 grade.

Ultra-Micrograin Carbide

- Hardness: 92.5 Ra

- Strength: 650,000 psi

- Cobalt Content: 12%

- Avg. Grain Size: .4 micron

- Characteristics: General purpose grade, harder and stronger than the other standard grades, may be particularly beneficial when cutting hard-to-machine materials, or for extending tool life in production applications.

The composition of carbide can be varied to change the material characteristics as desired for different applications. The three main variables are the tungsten carbide powder grain size, the amount of tungsten carbide powder and the amount of cobalt. Carbide flat blanks are commonly supplied in a C-2 material comprised of 94% tungsten carbide, 6% cobalt with an average grain size of 1.2 microns. Standard carbide round blanks are made of micrograin material with 90% tungsten carbide, 10% cobalt and .8 micron average grain size. Ultra-micrograin carbide round blanks are made of material with 88% tungsten carbide, 12% cobalt and .4 micron average grain size. This material is both harder and stronger than the standard micrograin.

SERVING OUR CUSTOMERS FOR OVER 45 YEARS

Centennial Carbide is a 45 year old company that specializes in carbide products.